In any industrial setting where electric motors drive key operations, unexpected motor failures can disrupt production and incur significant costs. Since repair works can take time to complete, be it a rewind or complete electric motor overhauling, having a replacement ready to go means downtime is kept at the bare minimum.

While the purchase of a spare motor represents a considerable investment, it can be a strategic asset that minimises downtime and safeguards your bottom line. Before committing to this investment, however, businesses should assess several critical factors.

Assessing the Need for a Spare Motor

1. Criticality to daily operations

When every minute counts, a malfunctioning motor can halt production, creating a domino effect of delays and lost revenue. In environments where operational continuity is paramount, having a spare motor on standby allows for immediate replacement, ensuring that production lines resume quickly and efficiently.

2. Uniqueness of the motor

Not all motors are created equal. Custom or specialised motors, often tailored for unique industrial applications, may not be repaired as easily as their general counterparts. Consulting with vendors or third-party repair experts can help determine the availability of replacement parts to reduce some of the lead time and whether keeping a spare is a cost-effective solution.

3. Age and obsolescence considerations

The lifecycle of your equipment and its motors plays a crucial role. As motors and the machinery they support age, manufacturers might phase out certain models at some point in the future, leading to extended lead times or even unavailability. Getting a spare motor before that happens can bridge the gap during periods when obtaining new parts is challenging, ensuring that operations do not suffer due to obsolescence.

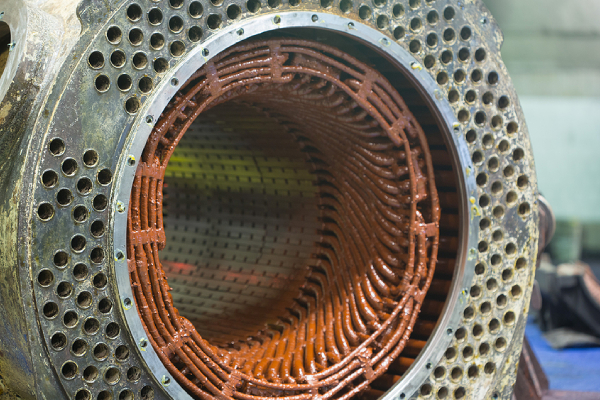

Ensuring Spare Motor Reliability

Acquiring a spare motor is only the first step; maintaining it in optimal condition is equally critical. After all, a neglected spare is no better than no spare at all. Here are key strategies to ensure reliability for your spare motors in storage:

Have a regular inspection schedule

Even in controlled storage environments, motors can undergo subtle degradation over time. Establish an inspection routine tailored to:

- Environmental Conditions: Motors stored in high-humidity, dusty, or temperature-variable areas may require checks every three to four months. In contrast, those in climate-controlled facilities might need less frequent inspections.

- Motor Type: General-purpose motors may suffice with biannual inspections, while specialised or high-performance motors—which tend to be more sensitive to moisture or lubricant issues—should be examined every three to four months.

- Usage Patterns: For motors in short-term storage (less than three months), a pre-use inspection might be sufficient if environmental conditions remained stable throughout the storage period. Long-term storage (beyond six months), however, should involve more frequent, quarterly or biannual checks.

Establish a dedicated maintenance programme for spares.

Implement a robust maintenance regimen that includes:

- Pre-Acceptance Testing: Before adding a spare motor into inventory, be it new or refurbished via services like motor rewinding in Singapore, conduct thorough testing to verify it meets operational standards. For spare motors stored offsite, don’t neglect to perform regular unscheduled spot checks even when the contracted storage provider includes periodic testing in your storage contract. Remember: trust but verify.

- Shaft Rotation Program: The heavy weight of motors places significant stress on bearing components. Constant exposure to warehouse vibrations—from passing forklifts or other machinery—can lead to uneven bearing wear (brinelling). Regularly rotating the motor’s shaft helps distribute this wear, preventing localised degradation that could cause rapid failure when the motor is eventually deployed.

- Addressing Gravity-Induced Wear: Over time, the weight of a rotor supported solely by bearings can lead to slight sagging, potentially resulting in rubbing or other issues upon energisation. Periodic maintenance can mitigate these risks, ensuring that the spare motor remains in peak condition.

Conclusion

A well-maintained spare motor is a vital component of a proactive strategy to ensure uninterrupted operations. By evaluating the key aspects of your motors and instituting a rigorous maintenance and inspection program, your organisation can significantly reduce the risk of costly downtime. Ultimately, the benefits of a strategically managed spare motor are well worth the investment involved, offering peace of mind and a tangible boost to operational efficiency.