Singapore’s climate is not kind to industrial equipment. High ambient temperatures, constant humidity and year-round operations create a perfect storm for electric motors to fail quietly and expensively. Unlike sudden breakdowns, these failures often build up over time, hiding in plain sight until production grinds to a halt.

Understanding what actually damages motors in hot, humid environments is the first step to preventing premature failures, costly downtime and unplanned replacements.

Below are five silent killers that industrial motors in Singapore face every day, and why proactive maintenance matters more here than almost anywhere else.

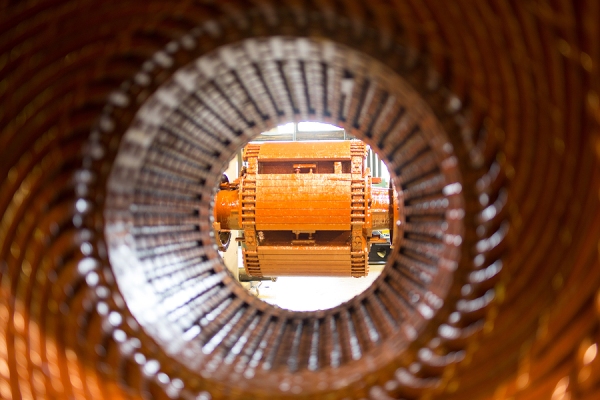

1. Excessive Heat Build-Up

Heat is the most obvious enemy, yet it is often underestimated. Electric motors are designed to operate within specific temperature limits, and Singapore’s consistently high ambient temperatures reduce the margin for error.

When ventilation is restricted, cooling systems are undersized or motors are operated close to maximum load for extended periods, internal temperatures rise quickly. Over time, this accelerates insulation ageing, reduces bearing life and weakens winding integrity. A motor that runs just 10°C hotter than its rated temperature can see its insulation lifespan cut in half.

This issue is especially common in enclosed plant rooms, rooftop installations and facilities where airflow is compromised by dust or poor layout. Heat damage does not announce itself loudly; it quietly erodes reliability until failure becomes inevitable.

2. Humidity And Moisture Ingress

Singapore’s humidity is relentless, and moisture is one of the most destructive forces acting on electric motors. Even when motors appear sealed, moisture can enter through cable glands, breathers, worn seals or during shutdown periods when temperature differences cause condensation.

Moisture weakens insulation resistance, encourages corrosion on windings and bearings, and increases the risk of electrical tracking. In severe cases, motors may fail insulation tests despite appearing mechanically sound.

This is why electric motor testing plays a critical role in preventive maintenance. Regular insulation resistance and polarisation index tests help identify moisture-related degradation long before it leads to short circuits or catastrophic failure.

3. Electrical Stress And Power Quality Issues

Power quality problems are another silent contributor to motor damage. Voltage imbalance, harmonics from variable frequency drives, frequent starts and stops, and unstable supply conditions all place additional electrical stress on motor windings.

In Singapore’s industrial environments, where automation and high-efficiency drives are widely used, motors are often exposed to non-ideal electrical conditions. These stresses cause localised heating within windings, accelerate insulation breakdown and increase the likelihood of partial discharge.

Without routine monitoring, these issues remain invisible until winding failure occurs. Proper electrical diagnostics, combined with load analysis, help ensure motors are operating within their design limits rather than slowly being pushed beyond them.

4. Bearing Wear Accelerated By Heat And Contamination

Bearings are often the first mechanical component to fail in electric motors, and Singapore’s environment speeds this up dramatically. Elevated temperatures reduce lubricant effectiveness, while humidity and airborne contaminants compromise grease quality.

As lubrication breaks down, friction increases, generating even more heat. This creates a vicious cycle that ends with bearing seizure, shaft damage or rotor misalignment. Unfortunately, bearing degradation is rarely audible in its early stages, especially in noisy industrial settings.

Vibration analysis and thermal monitoring support early detection of bearing issues, while motor thermal protection helps prevent damage from excessive heat. When combined with scheduled electric motor testing, these measures provide a clear picture of both mechanical and electrical health.

5. Inadequate Maintenance And Overlooked Ageing

The final silent killer is not environmental but operational. Motors that “seem fine” are often left out of maintenance schedules, especially if they are critical but rarely fail. Over time, ageing insulation, worn components and outdated protection systems accumulate risk.

In Singapore, where motors often run continuously to support essential processes, deferred maintenance compounds the effects of heat and humidity. What could have been addressed with minor servicing becomes a full motor replacement, often under emergency conditions.

A structured maintenance programme that includes inspection, cleaning, testing and performance trending transforms maintenance from reactive to predictive. It also provides valuable data to plan replacements strategically rather than reactively.

Why Early Detection Matters In Singapore

The common thread across all five silent killers is time. None of these issues cause immediate failure, but all of them shorten motor lifespan when left unchecked. Singapore’s climate accelerates this process, meaning motors here age faster than identical units operating in cooler, drier regions.

Early detection reduces unplanned downtime, improves safety and lowers total cost of ownership. More importantly, it gives engineers control. Instead of responding to failures, they can schedule interventions at the most convenient and cost-effective time.

Partnering With The Right Expertise

Industrial motors are too critical to leave to chance, especially in a climate as demanding as Singapore’s. Working with experienced specialists ensures testing, diagnostics and maintenance are performed to the right standards, using the right tools, at the right intervals.

For organisations looking to strengthen motor reliability and mitigate the silent killers discussed above, expert support makes a measurable difference. To learn more about professional testing, diagnostics and maintenance solutions tailored for Singapore’s operating conditions, contact MES.

A proactive approach today can prevent tomorrow’s failure, keeping motors running efficiently, safely and reliably in Singapore’s challenging environment.