A new year is the ideal moment for facilities managers, plant engineers, and operations teams to take a proactive approach towards industrial switchgear safety. Switchgear systems are the backbone of electrical distribution in factories, plants, and commercial facilities, yet they are often taken for granted until a fault occurs. A structured New Year checklist helps ensure operational reliability, regulatory compliance, and most importantly, the safety of personnel working around high-risk electrical environments.

Planned maintenance and early detection of wear not only prevent costly downtime but also extend the lifespan of critical assets. For businesses working with a trusted electrical engineering company in Singapore, this annual review becomes a strategic exercise rather than a reactive one.

Review Safety Documentation And Compliance Records

Safety documentation forms the foundation of any effective switchgear maintenance programme. Begin the year by reviewing all relevant operating manuals, single-line diagrams, risk assessments, and lockout/tagout procedures. These documents should accurately reflect the current configuration of your switchgear systems.

Check that compliance records align with local regulations and international standards such as IEC or IEEE, where applicable. Any modifications carried out during the previous year, whether upgrades, retrofits, or temporary workarounds, must be formally documented. Clear, up-to-date records ensure maintenance teams and contractors operate with consistent and accurate information.

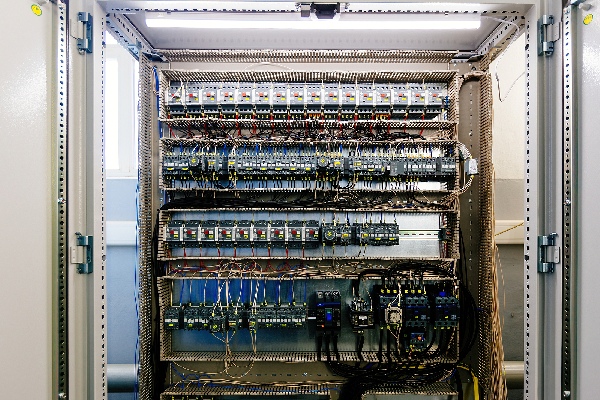

Conduct A Comprehensive Visual Inspection

Visual inspections remain one of the most effective ways to identify early warning signs of switchgear failure. Inspect enclosures for corrosion, moisture ingress, dust accumulation, or physical damage. Signs of overheating, such as discolouration or melted insulation, should be treated as immediate red flags.

Pay close attention to cable terminations, busbars, and insulating materials. Even minor cracks or loosened components can escalate into serious faults if left unaddressed. A thorough visual assessment sets the stage for deeper diagnostic testing later in the checklist.

Test Protective Relays And Circuit Breakers

Protective devices are designed to operate only under fault conditions, which means they can remain dormant for long periods. Regular testing ensures that relays, circuit breakers, and trip mechanisms respond correctly when needed.

Functional testing should include timing checks, trip verification, and calibration against manufacturer specifications. Failure of protective devices can expose equipment and personnel to severe hazards, making this step non-negotiable in any annual safety review.

Assess Electrical Connections And Torque Settings

Loose or improperly torqued connections are among the leading causes of switchgear failures. Over time, thermal cycling and vibration can cause fasteners to loosen, increasing resistance and heat build-up.

During the New Year inspection, verify torque settings for all accessible connections and tighten them according to specified values. Where necessary, thermal imaging can be used to detect hotspots that indicate poor contact or imbalance within the system.

Perform Insulation Resistance And Condition Testing

Insulation integrity plays a critical role in preventing short circuits and ground faults. Insulation resistance testing provides valuable insights into the condition of cables, busbars, and internal components.

Results should be compared with previous test records to identify trends or gradual degradation. Any abnormal readings warrant further investigation, as insulation failure often leads to unplanned outages and costly repairs if not addressed early.

Evaluate Mechanical Components And Operating Mechanisms

Switchgear safety is not solely an electrical concern. Mechanical components such as springs, linkages, shutters, and interlocks must operate smoothly to ensure correct switching sequences and personnel protection.

Inspect moving parts for wear, corrosion, or misalignment. Lubrication should be applied where appropriate, following manufacturer guidelines. Mechanical reliability is essential for safe isolation during maintenance activities and emergency situations.

Review Environmental Conditions And Housekeeping

Environmental factors significantly influence switchgear performance. Excessive humidity, heat, dust, or chemical exposure can accelerate component degradation and compromise safety.

Assess ventilation systems, air filters, and enclosure seals to ensure they are functioning effectively. Proper housekeeping around switchgear rooms, such as keeping areas clear of storage materials and debris, reduces fire risk and improves accessibility during emergencies.

Inspect Associated Motors And Auxiliary Equipment

Switchgear rarely operates in isolation. It often supports motors, drives, and auxiliary systems that are equally critical to plant operations. Reviewing the condition of connected equipment provides a more holistic view of electrical system health.

For facilities relying on electric motor rewinds in Singapore, the New Year is an excellent time to confirm that rewound motors are properly integrated and protected by suitable switchgear settings. Coordination between motor protection and switchgear ensures optimal performance and reduces the risk of cascading failures.

Verify Emergency Procedures And Staff Training

Even the best-maintained switchgear cannot eliminate all risks. Clear emergency procedures and trained personnel remain essential layers of protection. Review emergency shutdown processes, arc flash labels, and warning signage to ensure they are visible and accurate.

Confirm that staff training is current, particularly for employees authorised to operate or maintain switchgear. Refresher sessions at the start of the year help reinforce safe practices and keep teams aligned with updated procedures.

Plan Preventive Maintenance And Upgrade Strategies

An annual checklist should conclude with forward planning. Use findings from inspections and tests to prioritise maintenance tasks, component replacements, or system upgrades, especially when planning to modernise your switchgear for improved performance and compliance. Ageing switchgear may benefit from retrofitting modern protection relays or monitoring systems to enhance safety and reliability.

Working with experienced professionals allows organisations to transition from reactive repairs to predictive maintenance strategies, reducing long-term operational risks and costs.

Start The Year With Confidence And Safety

A structured New Year checklist for industrial switchgear safety supports uninterrupted operations, regulatory compliance, and a safer working environment. Regular reviews highlight vulnerabilities before they escalate, giving businesses greater control over their electrical infrastructure.

For organisations seeking dependable expertise, partnering with MES provides access to specialised knowledge, proven maintenance practices, and tailored solutions for complex electrical systems.