As the core of countless industrial operations, electric motors must be maintained as much as possible to ensure they run reliably day in, day out. One of the most common issues that chips away at this reliability is insulation failure—particularly turn-to-turn faults—which typically leads to unexpected downtime and costly repairs.

Understanding the mechanisms that degrade motor insulation, and applying pre-emptive diagnostics such as surge testing, can significantly enhance maintenance protocols and allow for timely electric motor rewinds in Singapore. This article goes over the technical processes of surge testing, its execution, integration with complementary diagnostic practices, and practical considerations for achieving optimal motor health.

Root Causes and Consequences of Insulation Degradation in Electric Motors

One of the earliest indicators of electrical motor failure is compromised conductor insulation. In many instances, this originates from substandard insulation at the winding turns, a flaw that may be introduced during initial manufacturing or while re-winding an existing motor. For motors already in service, insulation may experience deterioration due to many reasons:

- Chemical contamination: Deposits from oils, greases, solvents or industrial chemicals can chemically attack the insulating material, rendering it brittle or conductive over time.

- Mechanical stress: Repeated motor start-stop cycles or vibrations can cause micromotion, rubbing insulation off the windings, especially around the turns, ultimately resulting in thinning or breakdown.

- Thermal cycling: Elevated operating temperatures, combined with humidity cycles, can promote moisture ingress and accelerate insulation decay.

Given that approximately 80 per cent of motor failures initiate as turn-to-turn short circuits, it becomes evident that early detection of these nascent faults is essential. This is where surge testing plays a critical role within a comprehensive maintenance strategy.

What is Surge Testing For Electric Motors?

Surge testing is a non-intrusive method that subjects motor windings to carefully controlled high-voltage pulses, prompting them to generate diagnostic waveforms. By comparing these waveforms either against baseline signatures or against those of a known-good motor under similar conditions, technicians can detect incipient insulation weaknesses before they manifest as faults.

The primary advantages of surge testing are:

- Early detection of minor turn-to-turn faults, which otherwise would grow in severity under thermal or mechanical stress.

- Non-invasive diagnostics, meaning the motor need not be disassembled, thus minimising downtime.

- Cost avoidance, as identifying trouble early prevents more extensive damage and premature replacement.

Surge testing encompasses two principal approaches:

- Surge Comparison Test: This technique involves juxtaposing the waveform obtained from the motor under test with that of a reference motor known to be in good condition. Variations in crest factors, waveform symmetry or amplitude suggest degrading insulation or winding anomalies.

- Surge Waveform Test: Instead of direct comparison, this method examines the intrinsic shape and consistency of the waveform. Deviations from the expected pattern—such as additional humps, distortions, or phase shifts—indicate insulation degradation or shorted turns.

These tests may be augmented with complementary diagnostics, including impulse testing or partial-discharge analysis, to yield a holistic view of the winding’s integrity.

How Surge Testing Is Conducted

Equipment and Setup

A proper surge test requires a dedicated surge tester capable of generating high-voltage pulses, along with an oscilloscope or built-in waveform analyser to capture the resultant signals. Equipment such as Baker-type surge testers is commonly employed in the field. Given the specialised nature of these tools, it’s generally best to work with an electrical engineering company in Singapore to carry out such tests.

Procedure

1. Preparation: Disconnect the motor from power and ensure proper grounding. In the case of synchronous motors, isolate the exciter or lift slip-ring brushes to protect delicate rotor components.

2. Connection: The surge tester is linked to pairs of stator windings. If it is a three-phase motor, testing is sequential: phase A-B, B-C, and C-A.

3. Pulse Application: A high-voltage surge pulse is applied across each winding pair. It is crucial that technicians use voltage levels appropriate for surge testing—not the conventional over-voltage (hi-pot) levels. Misapplications, such as relying on outdated formulas like “2 × voltage + 1000 V”, can mask real issues or even damage the insulation system.

4. Data Capture: The oscilloscope records the resulting waveforms; these are then compared against a standards-based reference or a known-good waveform.

5. Analysis: Sophisticated waveform-analysis software may be used to highlight anomalies such as waveform skew, split peaks, or amplitude variances that could suggest insulation weakness or short circuits.

Interpreting Results and Deciding on Maintenance Action

Waveform irregularities serve as tell-tale signs of insulation distress. The technician must evaluate:

- Severity: Are the deviations minor (suggesting early-stage insulation wear), or pronounced (indicating potential imminent failure)?

- Trend: Is there a baseline of repeated testing data to assess whether the fault is stable or worsening?

- Appropriateness of intervention: Should the motor be cleaned, re-wound, or completely overhauled?

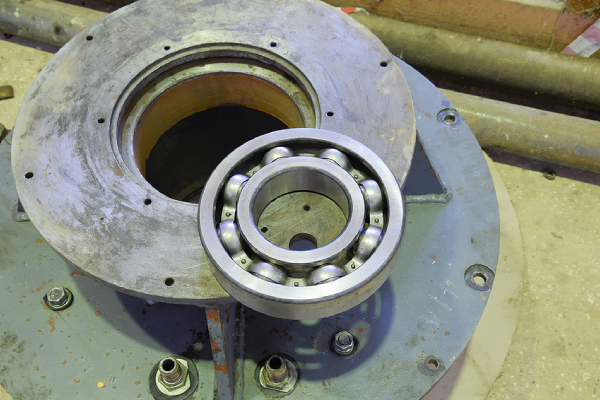

Here, integrating surge test findings with other diagnostic data from vibration analysis and thermography, for example, produces a more robust motor-health appraisal. Vibration analysis might uncover misalignments, roller bearing wear or shaft imbalance, while thermographic scans reveal hotspots arising from internal short circuits or over-temperature conditions.

Practical Considerations and Operational Safeguards

Surge testing, while invaluable, poses certain operational risks:

- Potentially destructive nature: By design, surge testing applies stresses that may find not only existing flaws but also latent weaknesses. Utilities and maintenance teams must be prepared to act should a component fail during testing.

- Field readiness: Before proceeding, confirm availability of spares, repair teams, and contingency plans. If the motor “fails” during testing, can it be patched temporarily, or must it be withdrawn immediately?

- Rotor safety: In large synchronous machines, the exciter and rotor insulation can be compromised if not properly isolated—retracting slip-ring brushes or disconnecting the exciter is not optional; it is mandatory.

Conclusion

Surge testing constitutes a fundamental pillar in the preventative maintenance and diagnostics of electrical motors to avoid costly breakdowns in the field. When combined with insulation resistance testing, thermal imaging, vibration analysis, and contamination control, surge testing becomes part of a robust, proactive maintenance ecosystem. Whether conducted as part of regular servicing or a comprehensive motor overhaul, surge diagnostics ultimately protect equipment uptime, reduce lifecycle costs, and bolster operational reliability.