Electric motor failures can stem from a wide range of factors, from issues in the power supply to mechanical malfunctions in the bearings. While it’s important to know the usual suspects to achieve a well-rounded inspection and upkeep regimen, it is also essential to learn about the lesser-known causes that can just be as devastating if they’re left to slip under the radar.

One such example of these problems is rotor bar issues. Specifically, cracked or broken rotor bars in AC motors can significantly disrupt performance as these internal defects tend to go unnoticed until they inflict considerable damage, making it essential for operators and technicians to understand their causes, symptoms, and diagnostic methods.

This article delves into the specific issue of rotor bar failure in AC motors, shedding light on how it occurs, why it matters, and how to identify it before it leads to costly breakdowns.

What Is AC Motor Rotor Bar Failure?

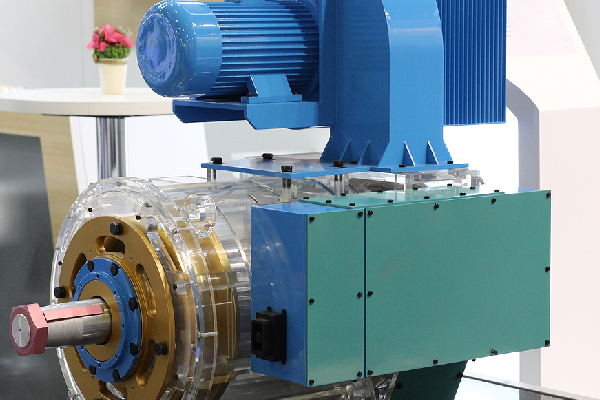

AC motor rotor bar failure refers to the degradation or breakage of the conductive bars embedded in the rotor of an AC induction motor. These bars, usually made from aluminium or copper, are integral to the formation of the rotating magnetic field necessary for the motor’s operation. When compromised, the motor may suffer from reduced performance, erratic torque output, and eventual overheating.

The Electric Power Research Institute states that rotor bar failure often results from prolonged exposure to thermal and mechanical stresses. These stresses degrade the material over time, weakening the structural integrity of the bars. Similarly, the International Electrotechnical Commission notes that misalignment, electrical imbalance, and unbalanced loads frequently act as catalysts, compounding the damage through accelerated wear.

Statistical data from the U.S. Department of Energy suggests that up to 40% of motor failures stem from rotor-related issues, highlighting the severity of this hidden vulnerability. The economic impact includes higher repair costs, prolonged downtime, and decreased energy efficiency. On the environmental front, compromised motors consume more electricity, contributing to unnecessary greenhouse gas emissions.

Routine inspections and preventive measures can dramatically reduce the risk of such failures, improving both operational reliability and energy efficiency.

Common Causes of AC Motor Rotor Bar Failure

Several contributing factors can lead to rotor bar failure in AC motors. Understanding these root causes can inform better maintenance strategies and equipment choices.

1. Mechanical Stress

Mechanical stress refers to the physical strain placed on rotor components during high-load operations. Frequent startups, excessive torque, and continuous exposure to vibration can all result in material fatigue. Over time, this stress leads to cracks or complete bar breakage. Preventive steps, such as proper alignment and timely lubrication, can significantly alleviate mechanical stress.

2. Electrical Imbalance

Electrical imbalances occur when there’s an unequal distribution of current among the rotor bars. This can stem from power supply issues, asymmetrical winding configurations, or faulty motor controls. Key impacts of electrical imbalance include:

- Elevated Current Flow: Uneven voltage causes certain bars to carry more current than others, leading to localised overheating.

- Magnetic Field Distortions: These imbalances produce irregular magnetic fields, resulting in fluctuating torque and inefficient operation.

- Increased Vibrations: Extra stress and magnetic inconsistencies translate into heightened vibrations, placing more wear on the rotor and other internal components.

- Accelerated Insulation Breakdown: The resulting heat from electrical stress degrades insulation materials, making the motor more prone to short circuits and internal faults.

Over time, these issues combine to compromise the motor’s reliability. Monitoring and correcting power supply quality can be a key preventive action.

3. Insufficient Cooling

Cooling systems in electric motors play a crucial role in dissipating heat generated during operation. Poor airflow, dust accumulation, or a malfunctioning fan can lead to thermal buildup within the rotor. When the rotor bars overheat, their mechanical and electrical properties deteriorate, increasing the likelihood of fractures or distortions.

Proper maintenance of the cooling system and periodic cleaning of air ducts and fans can help keep temperatures within safe limits.

4. Manufacturing Defects

Not all rotor failures are a result of operational conditions; some can be traced back to the manufacturing phase. Issues such as improper bonding, inconsistent dimensions, or substandard materials can introduce vulnerabilities right from the start.

These defects can:

- Cause uneven stress distribution during operation

- Lead to variances in electrical conductivity across bars

- Accelerate wear when combined with other operational stressors

In some instances, these factory-level flaws can only be identified through advanced diagnostic methods during scheduled electric motor overhauling.

Main Symptoms That May Indicate Eventual Rotor Bar Failure

Recognising early warning signs of rotor bar issues can prevent costly breakdowns. The following symptoms are commonly associated with impending rotor bar failure.

1. Abnormal Noises

Unusual motor sounds and noises during operation are often the first indication of internal mechanical issues. Rotor bar defects can create:

- Buzzing or Humming: Caused by disrupted magnetic fields

- Grinding or Rattling: May signal dislodged or fractured rotor bars

- Clicking: Often related to misalignment or loose components

- High-Pitched Squealing: Linked to overheating and insufficient lubrication

- Inconsistent Sound Patterns: A sign of uneven torque distribution

These auditory cues should prompt immediate investigation to avoid further internal damage.

2. Increased Vibration

When rotor bars break or loosen, the resulting imbalance creates abnormal vibration signatures. These can be detected using:

- Vibration Spectrum Analysis: Identifies harmonic frequencies tied to mechanical faults

- Sideband Monitoring: Tracks variations around key operating frequencies

- Time-Domain Signals: Captures sudden impulse patterns indicating structural faults

3. Overheating

Rotor bar defects increase electrical resistance, which in turn elevates operational temperatures. Key consequences include:

- Distorted Rotor Structure: Caused by prolonged exposure to heat

- Reduced Conductivity: Weakens the ability of rotor bars to handle electrical current

- Insulation Breakdown: Can result in short circuits and permanent damage

Thermal stress, if left unchecked, may render the motor inoperable. Continuous temperature monitoring is therefore essential.

Conclusion

AC motor rotor bar failures, while often hidden from plain sight, pose a substantial risk to motor reliability and performance. Understanding the underlying causes equips facility managers and technicians to take proactive measures, and recognising the common symptoms further enhances fault detection.

Moreover, by leveraging advanced diagnostic tools, rotor issues can be identified and resolved before resulting in significant operational downtime. All in all, regular maintenance, including generator maintenance, and timely intervention remain the best defences against rotor bar failure, ensuring optimal performance and extending the service life of AC motors.