When it comes to maintaining the performance and longevity of your generator, the break-in period after an overhaul is just as critical as regular maintenance. Generators are complex machines made up of various moving parts, including the generator itself and the alternator. After an overhaul, it is crucial to follow a proper break-in procedure to ensure the system runs smoothly and efficiently for years to come.

The Importance of Generator Break-In

After an overhaul, your generator’s components, including the alternator, need time to adjust and wear in properly. The break-in process allows internal parts to gradually adapt to their operational stresses. Without this critical step, you risk accelerating wear and tear, which could lead to costly repairs or even system failure.

The break-in period helps smooth out any microscopic imperfections that may have occurred during assembly, ensuring that all components work together in harmony. The result is reduced friction, improved performance, and a significantly lower risk of mechanical issues down the road.

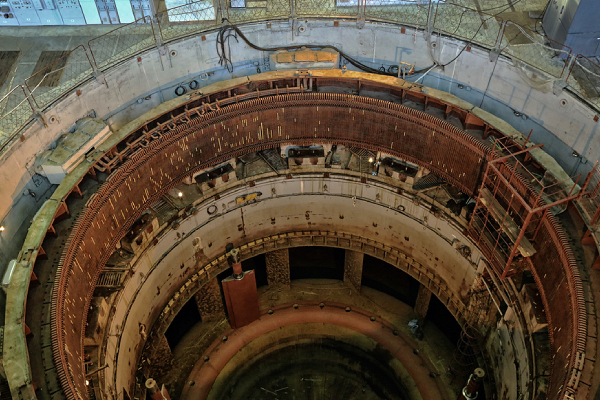

If your generator has undergone generator rewinding, it is especially important to go through a proper break-in. The rewinding process involves delicate work to ensure the coil windings are properly installed, and break-in helps ensure the system’s longevity by optimising the alignment and reducing friction between these newly installed components.

How the Generator Break-In Process Works

Think of the generator break-in as a controlled conditioning phase. Even after an overhaul, your generator still requires time to adjust to its environment. Here’s how the process typically works:

1. Initial Low-Speed Operation

In the first phase of break-in, the generator should run at a low speed without any load. This allows the engine components and the alternator to start moving together at a reduced pace, giving the internal parts time to settle in and adjust. It’s essential to monitor the generator during this phase to ensure that all temperatures remain within safe limits, and no unusual sounds or vibrations occur.

2. Gradual Load Increase

Once the generator has run smoothly at low speed for a while, the next phase involves gradually increasing the load. Start by applying a light load and monitor how the system responds. Gradually increase the load in stages, allowing the generator to handle higher power demands. This incremental approach ensures that the generator can adjust to the stresses of full operational loads without causing any sudden strain on its components.

3. Load Testing

After the generator has undergone the gradual load increase, it’s time for full load testing. This stage ensures that the generator can maintain its performance under the most demanding conditions. During this phase, closely monitor critical systems like the fuel system, the alternator, and the oil pressure. Any irregularities should be addressed immediately to avoid long-term damage.

Why Skipping the Break-In Process Is Risky

Skipping the break-in phase after an overhaul can lead to immediate and long-term damage. Without proper break-in, the friction between moving parts can lead to excessive wear. For example, improper seating of bearings can cause vibrations, increasing the risk of failure. Over time, this wear can escalate, leading to costly repairs and downtime.

Additionally, improper break-in may cause inefficient operation, resulting in poor fuel consumption or increased emissions. A well-broken-in generator will operate more smoothly, burn fuel more efficiently, and produce fewer emissions—making it not only more reliable but also more environmentally friendly.

Signs That Your Generator Has Properly Broken In

Once the break-in process is complete, you should notice several signs that indicate the generator is operating optimally:

- Smooth Operation: The generator should run smoothly, with no noticeable vibrations or irregular noises.

- Stable Output: The power output should be stable and consistent, with no sudden drops or fluctuations in voltage.

- Efficient Fuel Consumption: A properly broken-in generator should consume fuel more efficiently than before the process, which translates to cost savings in the long run.

Conclusion

Properly breaking in your generator after an overhaul is crucial for ensuring its optimal performance, efficiency, and longevity. The break-in process allows internal components, including the alternator, to settle into their roles, reducing friction and wear over time. By following a structured break-in procedure, you’ll minimise the risk of costly repairs and ensure that your generator can operate at peak performance for years to come. Whether you’re performing generator rewinding or HV motor rewind for industrial equipment, proper post-overhaul care ensures reliable, efficient operation.